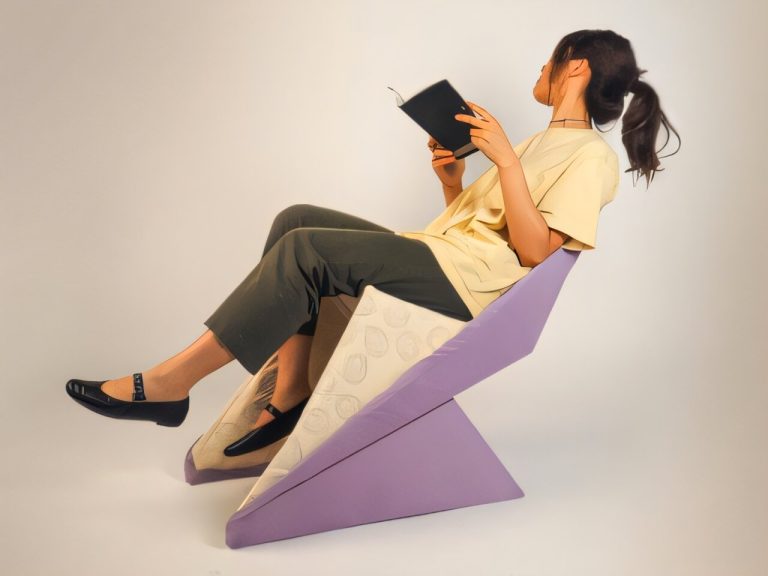

The flat form chair in action. Credit: Carnegie Mellon University

Researchers from Human Computer Institute Institute (HCII) and Robotics Institute (RI) of Carnegie Mellon University have introduced a new method for making functional objects flatly using a computer controlled sewing machine.

The team includes Sapna Tayal, undergraduate student at the design school; Lea Albaugh, Mark Stehlik Fellow from postdoctoral education in HCII; James McCann, associate professor in RI; and Scott E. Hudson, professor and associate department head of education in HCII.

“Flat-to-Shape” refers to objects that can be transformed from a flat leaf into a three-dimensional form thanks to methods such as flexion, folding or assembly of connected parts. Previous methods have deployed small -scale beach techniques to reduce construction time on 3D printers and laser cutters, but these methods often required a long manual assembly and can be difficult to evolve. The CMU team has seen an opportunity to rely on these techniques and create a method to make functional and rapid deployment objects.

“Sewing machines are an accessible manufacturing technology. Some of these machines have a calculation control that unlocks many manufacturing possibilities and this allows us to sew on a larger scale, and are generally used to make padded blankets,” said Albaugh. “In our project, we focused on using the CNC sewing machine in a new way. “”

Longarm courtyard machine. The fabric is stretched on the rolls. Credit: Carnegie Mellon University

The team method uses the sewing machine to sew the pockets between the layers of fabric, and rigid panels are inserted in the pockets. Several types of fabrics can be used, ranging from muslin for robust applications to more delicate fabrics for decorative purposes. Materials can also be personalized in panel panel to adapt to the needs of each object.

Researchers have shown how materials can be chosen to support a variety of functional objectives, such as the use of thicker plywood for a human weight support chair and personalized LED panels with a transparent fabric for a functional lamp. In addition, the technique also allows additional mechanisms such as cords, magnets and hook and loop fasteners to direct and stabilize flat transitions.

“It was a fun experience to describe a new type of manufacturing space by exploring materials and practical manufacturing,” said Tayal. “As a design in design, I often make templates to make unique objects, but having the opportunity to refine and explain a process in a research context, especially on such an interesting machine, was really exciting.”

The new method has enabled researchers to achieve their objective of creating elements large enough for the whole body human interactionslike sitting, carrying or carrying while being portable and adaptable to several parameters.

In their paperEntitled “Creation of objects deployable on the scale of furniture with a computer controlled sewing machine”, they describe a collection of functional artifacts with shape to shape they have created with their technique, including an extra table, a backpack, a chair and a lamp. Each object incorporated different variations in insertion of rigid panels in flexible fabric leaves. The newspaper was accepted at 2025 Conference on human factors in IT systems (Chi).

The project was one of the presentations of the student -based company of the Tayal Industrial Merit Prize for the Merit presentations of students of the Society of America (IDSA) for the Tour du District.

More information:

Tayal, S. et al. Creation of objects deployable on the scale of furniture with a computer controlled sewing machine, DOI: 10.1145 / 3706598.3713735,, Drive.google.com/file/d/1qimwy… dhuqr0pgv9dizzf/View

Learn more about flat objects to form and find complete paper On his website.

Supplied by

Carnegie Mellon University

Quote: Transform flat objects using sewing technology (2025, April 22) Extract on April 23, 2025 from https://techxplore.com/News/2025-04-flat-technology.html

This document is subject to copyright. In addition to any fair program for private or research purposes, no part can be reproduced without written authorization. The content is provided only for information purposes.