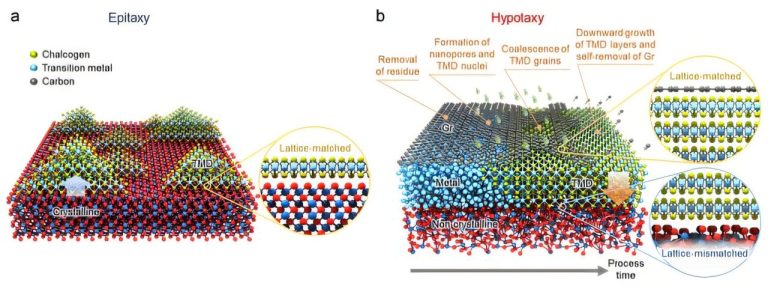

Schematic comparison between TMD growth via epitaxy and hypotaxis. Credit: Nature (2025). DOI: 10.1038 / S41586-024-08492-9

A research team has successfully developed a new summary technology for 2D semiconductors. This technique allows direct growth of monocrystallic 2D semiconductors at the plate scale on various substrates. Research is published In Nature.

With the advancement of artificial intelligence technology (AI), the demand for improved performance of semiconductors has increased, as well as active research on the reduction of energy consumption in Semiconductor devices. Consequently, new semiconductor materials to replace conventional silicon attract attention.

Among them, 2D materials such as transitional metal dichalcogenids (TMDS) have been highlighted as new generation semiconductors because of their thin structure and their excellent electrical properties. However, there is currently a lack of mass production technology to synthesize them in high quality and use them industrially.

The most promising method of synthesis to date, Chemical steam depot (CVD), suffers from problems such as the degradation of electrical properties and the need to transfer TMD cultivated to different substrates, adding additional complexity to the process. In addition, the “epitaxy” method, which increases TMDs on highly crystalline substrates, also requires a transfer process and is limited to specific substrates.

Consequently, the development of advanced 3D integration technology based on high-quality TMDs has become a crucial challenge in the modern semiconductor industry, further emphasizing the urgent need for a new TMD synthesis method.

To solve this problem, the research team has developed a whole new growth method. They introduced an approach that exploits 2D materials, such as graphene and Hexagonal boron nitride– as models, guiding the alignment of TMD crystals to allow the synthesis of perfectly monocrystalline TMD films on any substrate. This technique, called “hypotaxie”, was developed for the first time in the world. The name “hypotaxis” has been derived by combining “hypo” (which means “down”) and “taxy” (meaning “arrangement”), reflecting the characteristic of growth downwards synthesized.

(From top to bottom) Schematic representation of growth in TMD growth over time, transmission electron microscopy images (TEM), diffraction models and TEM images in transverse Cutting TMD growth using hypotaxy. Credit: Nature (2025). DOI: 10.1038 / S41586-024-08492-9

This technology has a significant industrial potential because it allows the growth of monocrystalline TMD at a low temperature (400 ° C), which makes it compatible with the manufacturing processes of existing semiconductors. In addition, the graphene model naturally disappears without requiring post-elimination process, and the thickness of the metal film can be controlled with precision to regulate the number of TMD layers. These distinctive features distinguish hypotaxis from existing methods.

In addition, the semiconductor devices made using TMDS synthesized by hypotaxis have demonstrated mobility of high-load carriers and excellent uniformity of devices, indicating that hypotaxis has great potential to contribute to the development of high-performance 2D semiconductors with high generation.

Beyond its application in the growth of 2D semiconductors, hypotaxis is recognized as an innovative technique applicable to the synthesis of all crystalline materials. Not only overcoming the limits of traditional semiconductor manufacturing methods, but also for activation precise control On the orientation and crystal structure through models, this approach presents a revolutionary method which has never been proposed before.

Graphene formed of nanopore via oxygen plasma and mos2 synthesized at 400 ° C using this method. Credit: Seoul National University College of Engineering

Professor Gwan-Hyoung Lee, who led research, stressed the importance of the study, declaring: “The hypotaxis technique that we developed overcomes the limits of epitaxy, a concept proposed for the first time in the 1930s and a fundamental pillar of modern electronic development. Material engineering. “”

Donghoon Moon, The First Author of the Paper, Refleted On The Research Process, Saying, “The Greatest Challenge was breaking away from the Convention Perception of Epitaxy, which has been the standard for synthesizing various high-quality Materials. Counterturituitive Perspective On Epitaxe, I Hope this Achievement Serves as a Catalyst for Groundbreaking Research in Areas Such as New Material Development and the Synthesis of Novel Lattice Structures.

More information:

Donghoon Moon et al, hypotaxis of the dichalcogenids of metal of single transition to the scale of the plate, Nature (2025). DOI: 10.1038 / S41586-024-08492-9

Supplied by

National University of Seoul

Quote: New Synthesis Technology for 2D semiconductors with monocrystal crystal

This document is subject to copyright. In addition to any fair program for private or research purposes, no part can be reproduced without written authorization. The content is provided only for information purposes.