We could produce concrete at 30% stronger by treating and adding charred coffee Grounds to the mix, have discovered researchers in Australia.

Their smart recipe could solve several problems at the same time.

Each year, the world produces 10 billion kilograms (22 billion pounds) of coffee waste worldwide. Most are found in the discharges.

“The elimination of organic waste poses an environmental challenge because it emits large amounts of greenhouse gases, including methane and carbon dioxide, which contribute to climate change“” explain The engineer at the University Rmit Rajeev Roychand when research was published in 2023.

https://www.youtube.com/watch? Frameborder = “0 ″ allow =” accelerometer; Autoplay; Clipborat-writing; encrypted media; gyroscope; image in an image; Web-share “RefraierPolicy =” Strict-Original-Ohen-Cross-Origin “Allowerlscreen>

With a Booming construction market worldwideThere is also an ever -increasing demand for a high intensity of resources, also causing another set of environmental challenges.

“Continuous extraction of natural sand in the world – generally taken from river beds and banks – to meet the growing demands of the construction industry has a significant impact on the environment”. said The engineer Rmit Jie Li.

“There are critical and lasting challenges in maintaining a sustainable sand supply due to the finished nature of environmental resources and impacts of sand exploitation. With a circular economy approach, we could keep biological waste outside the discharge and also preserve our natural resources as sand.”

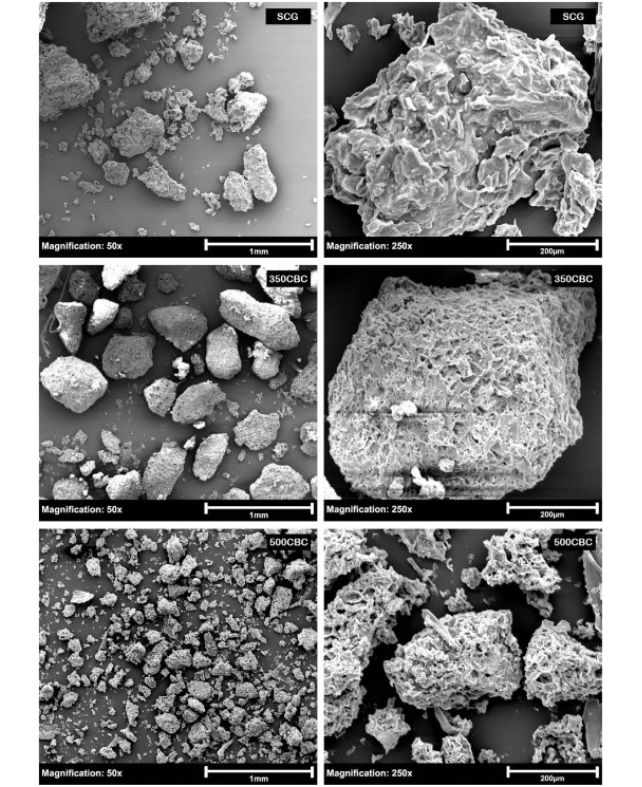

Organic products and coffee grounds cannot be added directly to concrete because they disclose chemicals that weaken the strength of the building material. Thus, using low energy levels, the team heated coffee waste at more than 350 ° C (around 660 ° F) while depriving it of oxygen.

This process is called pyrolysant. It breaks down the organic molecules, resulting in a porous charcoal rich in carbon called biocharwhich can form links with and thus integrates into the cement matrix.

Roychand and his colleagues also tried to pyrolyzer the coffee ground at 500 ° C but the resulting biochar particles were not as strong.

The researchers warned that they still had to assess the long -term sustainability of their cement product. They are now working to test how hybrid coffee behaves under cycles of gel / thaw, water absorption, abrasions and many other stressors.

The team also works on the creation of biochars from other sources of organic waste, including wood, food waste and agricultural waste.

“Our research is in the first stages, but these exciting results offer an innovative way of considerably reducing the quantity of organic waste that goes to discharge.” said RMIT SHANNON KILMARTIN-LYNCH engineer.

“Inspiration for my research, from an indigenous point of view, is to take care of the country, to guarantee that there is a lasting life cycle for all the materials and to prevent things from entering the discharge to minimize the impact on the environment.”

Their research was published in the Journal of Cleaner Production.

A previous version of this article was published in September 2023.