Swiss scientists have created a new flexible, biodegradable and even edible plastic material. The secret? It’s always alive.

The equipment, which was created by an EMPA team in Switzerland, manages to balance biodegradability with tenacity and versatility – a feat which is far from easy in materials science.

Researchers treated the fibers of the mycelium (the root -shaped part) of the split mushroom (Municipality of Schizophyllum) in a liquid mixture, without killing or destroying their natural biological functions.

The resulting gel material is called living fiber dispersions, or LFD, and it can be molded in many different forms. It also fully uses the additional substances produced by fungi, where Other biomaterials could simply use central fungal cells.

“The fungus uses this extracellular matrix to give itself a structure and other functional properties”, ” said Scientist of Ashutosh Sinha materials, Empa. “Why should we not do the same?”

By developing a specific strain of divided ice, researchers were able to encourage the growth of two molecules in particular: Schizophyllan polysaccharide and hydrophobin. These molecules are crucial to give LFD its attractive properties.

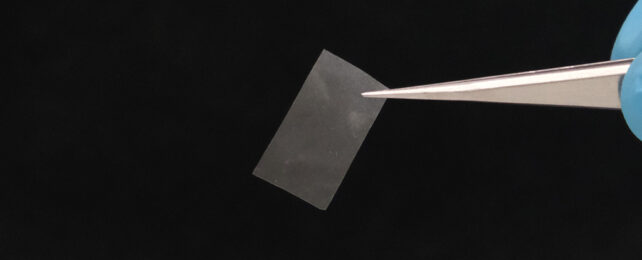

A possible use of the material is like a thin film with a very high tensile resistance. Researchers suggest that it could potentially be used in compost bags which rot naturally as well as the composting of their content, or in super thin biodegradable batteries.

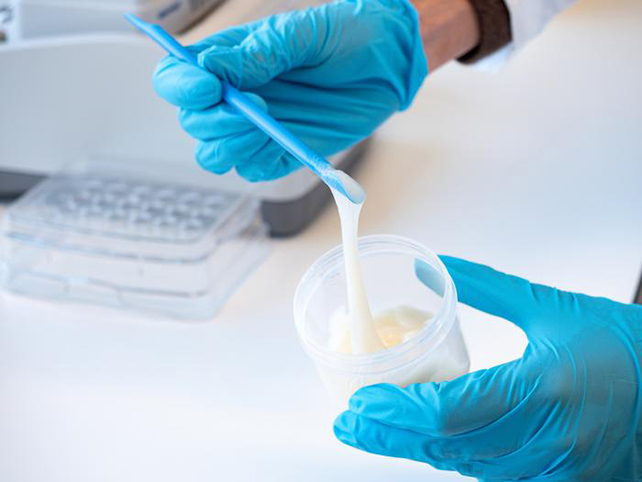

LFD also works well as an emulsifierA substance that allows two other materials to mix and bond together when they would not do it otherwise. The emulsifiers are important in the production of food and cosmetics, found in everything, from ice cream to shampoo.

Because it is still alive, the fungus continues to release more from its key molecules.

“It is probably the only type of emulsion that becomes more stable over time”, ” said Sinha.

And because it comes from the edible Communner S. Mushroom, this LFD is also completely non -toxic – you can even eat it without any problem. Regarding food and cosmetics, this is another big plus for equipment.

There is also the potential of many future research here, because the team thinks that the approach used here could be modified for produce materials With other specific properties, such as a manufacturer of on -demand materials.

Scientists often turn to nature for inspiration, whether they develop Medication administration methods Or Construction robotsAnd we see an increasing number of fungi studies as a basis for new materials.

Biomaterials based on fungi could act as Plastic alternativesand to form clothes that are able to repair. There are many advantages in materials that combine natural and synthetic.

Researchers hope to find more and more practical uses for LFD over time, following a long line of Materials inspired by nature – Proof that the natural world around us is the best laboratory there is.

“Biodegradable materials always react to their environment,” said The scientist of the materials Gustav Nyström, of the EMPA.

“We want to find applications where this interaction is not an obstacle but perhaps even an advantage.”

Research was published in Advanced materials.