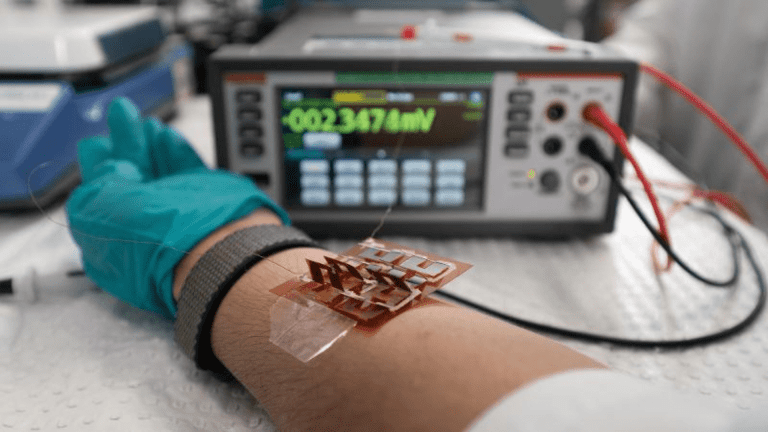

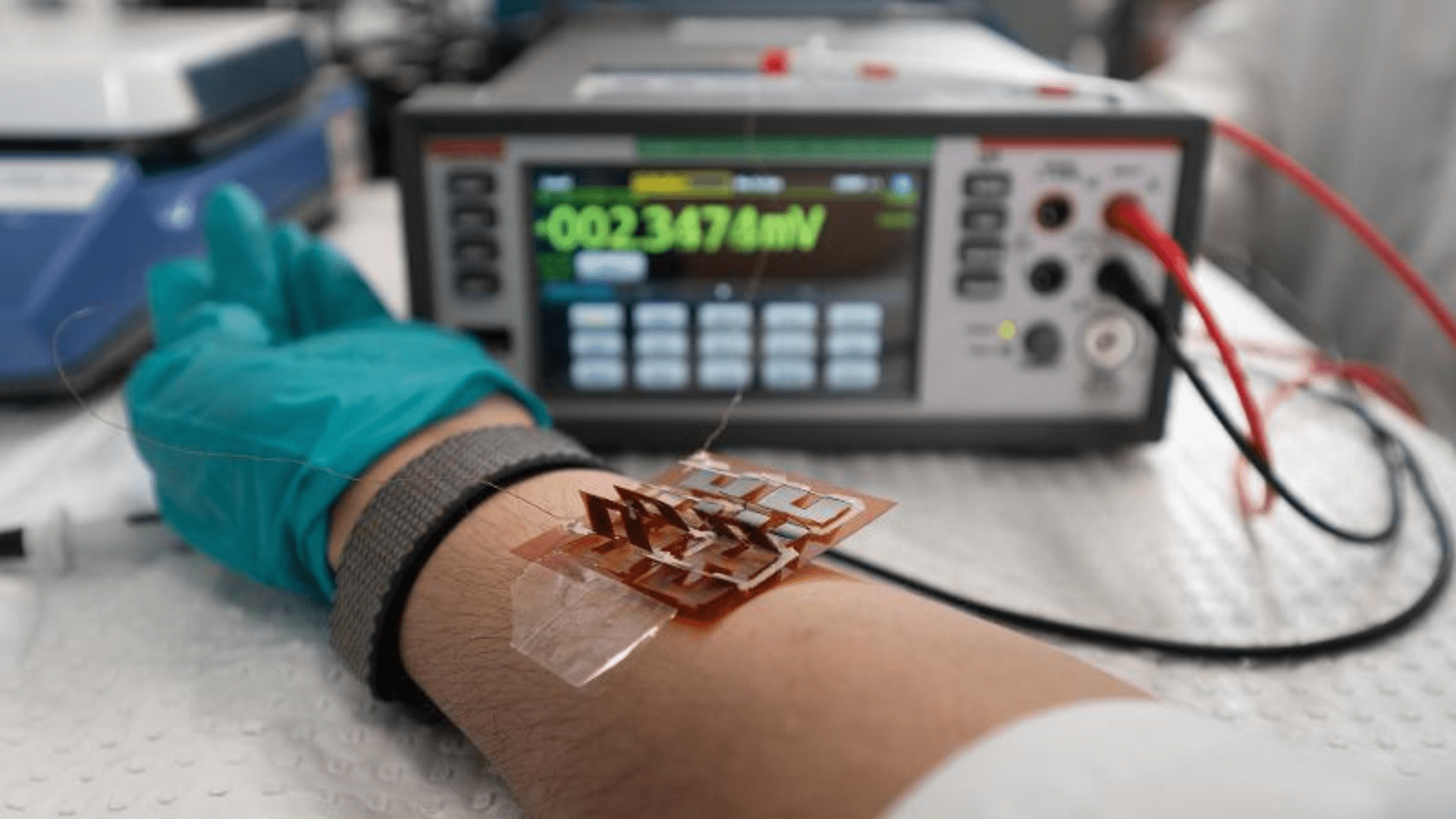

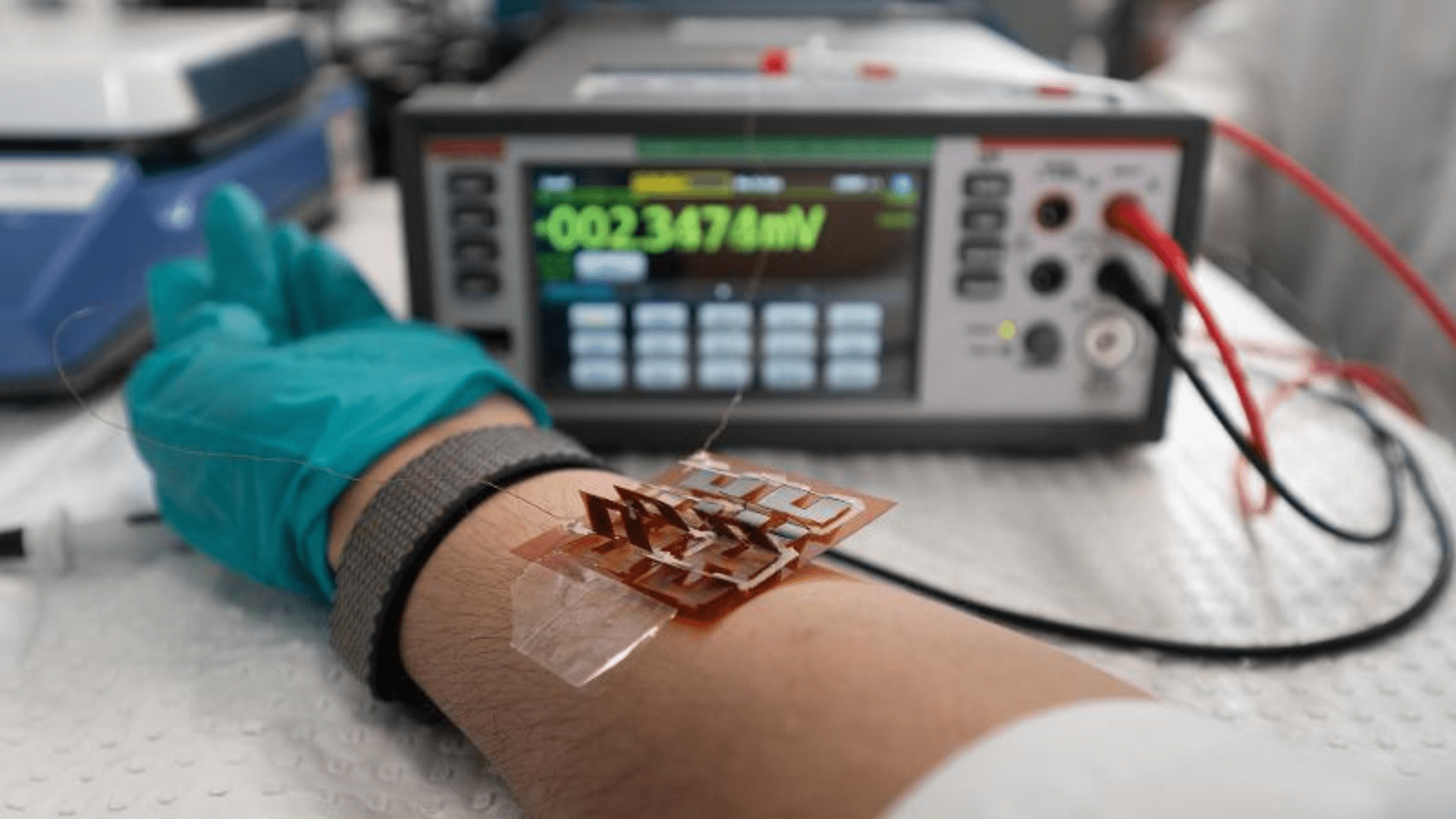

Researchers at the Queensland University of Technology (QUT) have developed an ultra-thin, flexible film capable of generating electricity from body heat. The film could power next-generation wearable technology, eliminating the need for batteries.

Sustainable energy source

Additionally, the technology could cool electronic chips, allowing computers or smartphones to operate more efficiently. Professor Zhi-Gang Chen and his team published their findings in the journal Science. The researchers said they had overcome a major challenge in creating flexible thermoelectric devices that converted body heat into energy.

Their approach offers a potential source of sustainable energy for wearable technology and a cooling method for chips.

“Flexible thermoelectric devices can be worn comfortably on the skin where they efficiently transform the temperature difference between the human body and the surrounding air into electricity,” Professor Chen. said. “They could also be applied in a tight space, such as inside a computer or cell phone, to help cool chips and improve performance.”

Chen says there are many potential applications, including personal thermal management, where body heat powers an HVAC system. “However,” he said, “challenges such as limited flexibility, complex manufacturing, high costs and insufficient performance have prevented these devices from reaching commercial scale.”

Cost-effective technology

Most research in this area has focused on bismuth telluride-based thermoelectrics, valued for their high properties. Its high properties convert heat into electricity, making it ideal for low-power applications such as heart rate, temperature or motion monitors.

The researchers introduced a cost-effective technology to fabricate flexible thermoelectric films in this study. They used tiny crystals called “nanobinders” that form a consistent layer of bismuth telluride sheets, improving efficiency and flexibility.

“We have created an A4-sized printable film with record thermoelectric performance, exceptional flexibility, scalability and low cost, making it one of the best flexible thermoelectric films available,” said Professor Chen. Mr. Wenyi Chen, the first author of the study, explained their technique along with other potentially cheaper and durable systems.

He said: “This material flexibility shows the vast possibilities offered by our approach to advancing flexible thermoelectric technology. »