How many robots do you need to screw a bulb?

The answer is more complicated than you think.

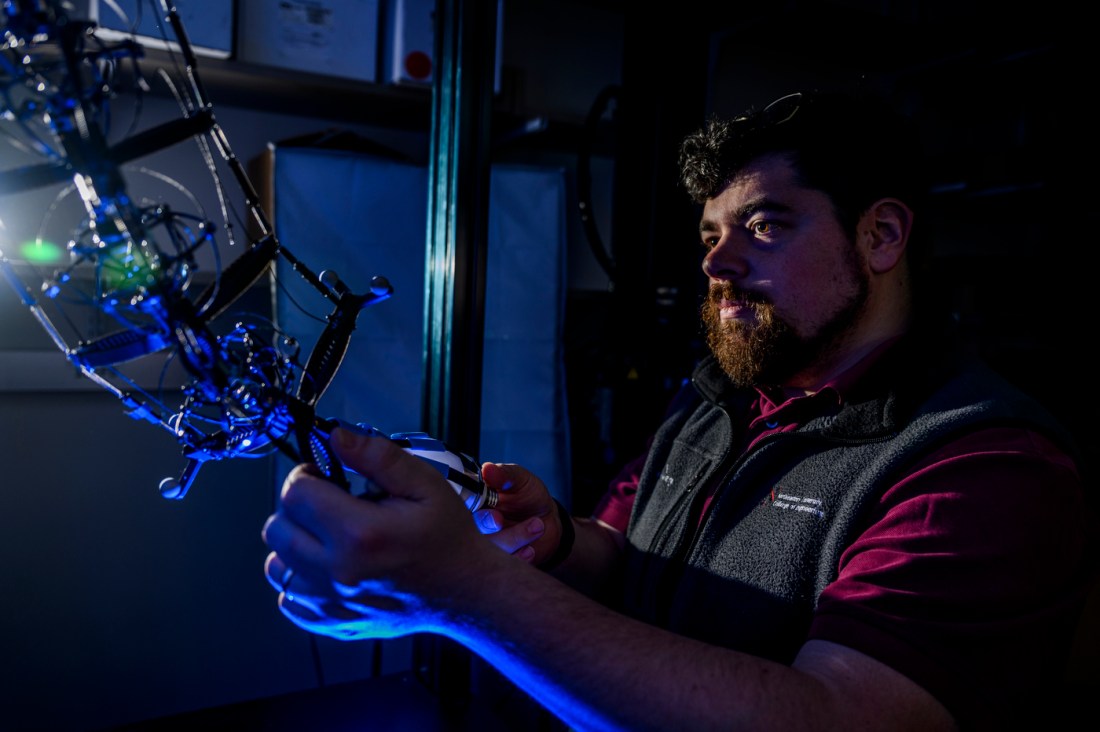

New research From the Northeastern University upsets the enigma by making a robot that is both flexible and sensitive enough to manage the bulb, and strong enough to apply the necessary couple.

“What we have found is that by thinking about robots bodies and how we can make them new materials, we can really make a robot that has the advantages of rigid and soft robots,” explains Jeffrey Lipton, assistant professor of mechanical and industrial genius in Northeastern.

“It is flexible, expandable and conforming like an elephant trunk or an octopus tentacle, but can also apply couples like a traditional industrial robot,” he adds.

Lipton explains that there are currently two types of robots around the world: rigid (or hard) robots and soft robots.

Rigid robots are your typical industrial robots. They start and stop automatically to perform precise high -speed tasks – and often a great danger – for humans.

“You like to put them behind cages because if they move quickly enough to be useful, they probably also move fairly quickly enough to injure you,” explains Lipton.

These robots are excellent to run things, capable of applying a couple from a distance, says Lipton.

The soft robots, on the other hand, are bi -sided – think of an elephant trunk or a knife of octopus – and can reach and pull and interact in complex environments and around people.

“If I have a robot that is spongy like a pool noodle, it could slap me and it can sting a little, but it will not break a bone,” explains Lipton.

So what has it to do with a bulb?

Well, a rigid machine has the necessary couple, but a soft robot has handling and flexibility to manage such a delicate task.

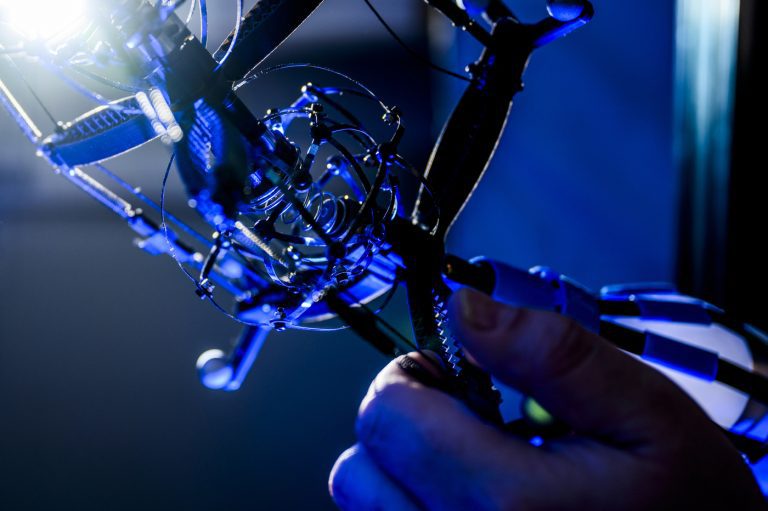

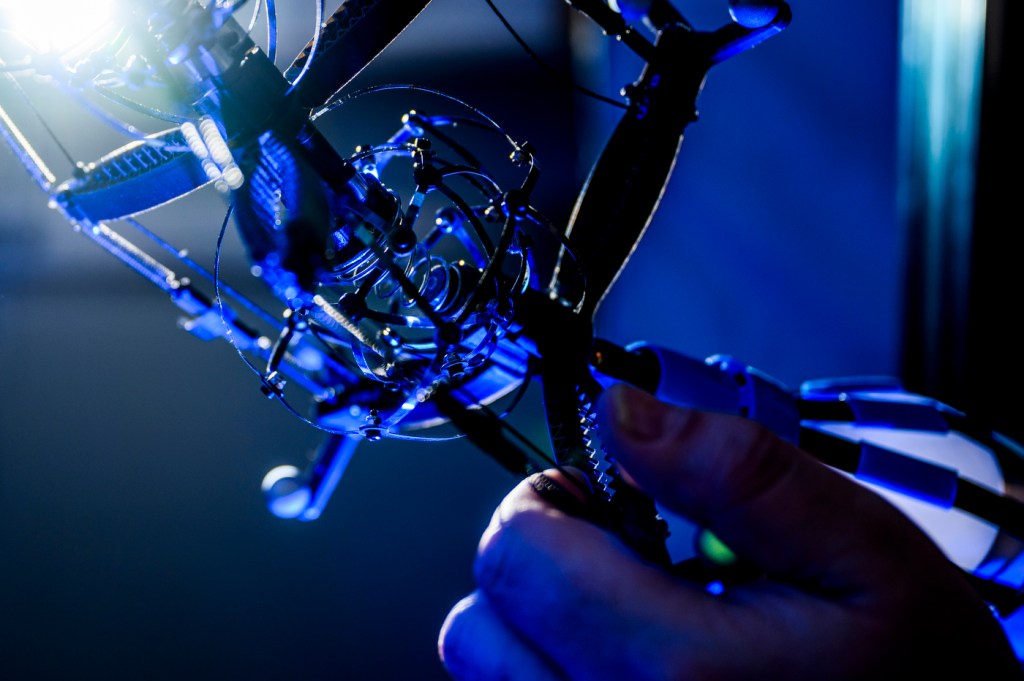

But in new research Posted in Science RoboticsLipton has developed a hard and soft hybrid robot.

The hybrid robot works with the kind authorization of a new equipment that works similar to the constant speed joints that you find connecting a wheel to the axle of your car.

In a car, the CV joints allow a wheel to move from top to bottom and bounce while keeping the axle in place, turning, explains Lipton. But they are made of hard and rigid components.

“Ours, we can really make mild and flexible and foldable,” explains Lipton. “It’s a new type of joint, but you can model it and then you can make it equipment.”

It is a new approach to the design of robots.

“Everything is by conceiving the shape, and it makes us really different from most soft robots where they focus on changing the chemistry,” explains Lipton.

The approach led to a new type of robot arm – as well as a new response to the number of robots necessary to screw a bulb.