File it under “This isn’t supposed to happen!” “. In one experiment, scientists observed a metal healing itself. If this process could be fully understood and controlled, we could be at the start of a whole new era of engineering.

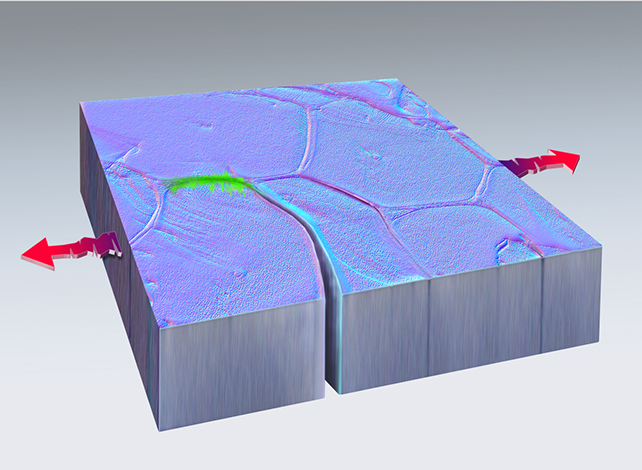

In a study published last year, a team from Sandia National Laboratories and Texas A&M University tested the metal’s resilience, using a specialized transmission system. electron microscope technique for pulling the ends of metal 200 times per second.

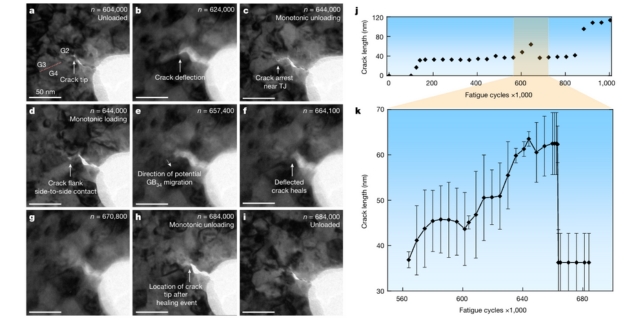

They then observed self-healing on a very small scale in a 40-nanometer-thick piece of platinum suspended in a vacuum.

Cracks caused by the type of stress described above are called fatigue damage: repeated stresses and movements that cause microscopic breaks, eventually causing machines or structures to break.

Surprisingly, after about 40 minutes of observation, the crack in the platinum began to heal and repair itself before starting again in a different direction.

“It was absolutely breathtaking to watch first hand,” said Sandia National Laboratories materials scientist Brad Boyce when the results were announced.

“We certainly weren’t looking for it. What we confirmed is that metals have their own intrinsic, natural ability to heal themselves, at least in the case of nanoscale fatigue damage .”

These are exact conditions, and we don’t yet know exactly how this happens or how we can use it. However, if you think about the cost and effort required to fix everything bridges From engines to phones, it’s unclear what difference self-healing metals could make.

Although this observation is unprecedented, it is not entirely unexpected. In 2013, Michael Demkowicz, a materials scientist at Texas A&M University, worked on a study predict that this type of nanocrack healing could occur, driven by the tiny crystal grains inside the metals essentially moving their boundaries in response to stress.

Demkowicz also worked on this study, using computer models to show that his decade-old theories about the self-healing behavior of metal at the nanoscale matched what was happening here.

The fact that the self-repair process took place at room temperature is another promising aspect of the research. Metal generally requires lots of heat change shape, but the experiment was carried out in a vacuum; It remains to be seen whether the same process will occur in conventional metals in a typical environment.

One possible explanation involves a process known as cold weldingwhich occurs at room temperature when metal surfaces come close enough for their respective atoms to become entangled.

Typically, thin layers of air or contaminants interfere with the process; in environments like the vacuum of space, pure metals can be brought close enough together to literally stick.

“I hope this discovery will encourage materials researchers to consider that, under the right circumstances, materials can do things we didn’t expect.” said Demkowicz.

The research was published in Nature.

An earlier version of this article was published in July 2023.