On April 1, 2025, the Taiwanese manufacturer TSMC presented The most advanced micropuce in the world: the 2 nanometers (2nm) chip. Mass production is expected for the second half of the year, and the TSMC promises that it will represent a major step in performance and efficiency – potentially rehabilitating the technological landscape.

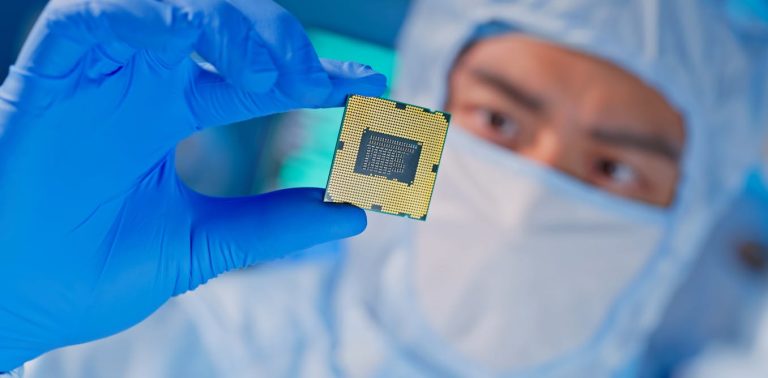

Micropuces are the foundation of modern technology, found in almost all electronic devices, electric toothbrushes and smartphones with laptops and household appliances. They are made by the superposition and engraving of materials such as silicon to create microscopic circuits containing billions of transistors.

These transistors are actually tiny switches, managing the flow of electricity and allowing computers to operate. In general, the more a chip contains transistors, the faster and more powerful it becomes.

The micropile industry is constantly striving to wrap more transistors in a smaller area, leading to faster, more powerful and energy efficient technological devices.

Compared to the previous most advanced chip, known as 3NM chips, 2 nm technology of TSMC should offer notable advantages. These include a 10% to 15% of computer speed At the same level of power or a reduction of 20 to 30% of energy consumption at the same speed.

In addition, the density of the transistor in 2 nm chips is increased by around 15%, in addition to 3 nm technology. This should allow devices to operate more quickly, consume less energy and effectively manage more complex tasks.

The Taiwan micropile industry is closely linked to its safety. It is sometimes called the “silicon shield” because its widespread economic importance encourages the United States and the allies to defend Taiwan against the possibility of a Chinese invasion.

TSMC recently struck a Offer of $ 100 billion (76 billion pounds sterling) to build five new American factories. However, there is an uncertainty as to whether the chips 2 nm can be Made outside TaiwanAs some officials are concerned, this could undermine the security of the island.

Created in 1987, TSMC, which means Taiwan Semiconductor Manufacturing Company, manufactures fleas for other companies. Taiwan represents 60% of the world “foundry” market (outsourcing the manufacture of semiconductors) and the vast majority of this comes of TSMC alone.

Super advanced TSMC microchips are used by other companies in a wide range of devices. He makes apples Processors of series A Used in iPhones, iPads and Macs, it produces NVIDIA graphic treatment units used for automatic learning and AI applications. It also manufactures Ryzen and Epyc of AMD processors used by Superordinators from around the world, and it produces Snapdragon processors of Qualcomm, used by Samsung, Xiaomi, OnePlus and Google Phones.

In 2020, TSMC launched a special miniaturization process of micropuce, called 5nm Finfet technologyThis played a crucial role in the development of smartphone and high performance understanding (HPC). HPC is the practice of simultaneously operating processors on complex IT problems.

Two years later, TSMC launched a 3nm miniaturization process Based on even smaller microchips. This has further improved performance and energy efficiency. Apple A series A processor A, for example, is based on this technology.

Michael VI / Shutterstock

Smartphones, laptops and tablets with 2 NM fleas could benefit from better performance and the lifespan lifespan longer. This will lead to smaller and lighter devices without sacrificing power.

The efficiency and speed of fleas 2 NM have the potential to improve AI -based applications such as voice assistants, language translation in real time and autonomous IT systems (those designed to operate with minimum or without any entry). Data centers may undergo reduced energy consumption and improve processing capacities, contributing to environmental sustainability objectives.

Sectors such as autonomous vehicles and robotics could benefit from the increase in the process of processing and reliability of new chips, which makes these technologies safer and more practical for general adoption.

All this seems really promising, but although 2NM chips represent a technological step, they also pose challenges. The first is linked to the complexity of manufacturing.

The production of 2 nm fleas requires advanced techniques such as Extreme ultraviolet lithography (EUV). This complex and expensive process increases production costs and requires extremely high precision.

Another big problem is heat. Even with relatively lower consumption, as transistors decrease and densities increase, the management of heat dissipation becomes a critical challenge.

Overheating can have an impact on the performance and sustainability of fleas. In addition, on such a small scale, traditional materials such as silicon can reach their performance limits, requiring the exploration of different materials.

That said, improved computing power, energy efficiency and miniaturization allowed by these chips could be a bridge to a new era of calculation of consumers and industrialists. Smaller fleas could lead to breakthroughs in the technology of tomorrow, creating devices not only powerful but also discreet and more respectful of the environment.